Dental 3D print methods | Everything you need to know

------------------------------------------------------------------------------------------------------------------------------------------

Dental 3D print methods revolutionized dentistry

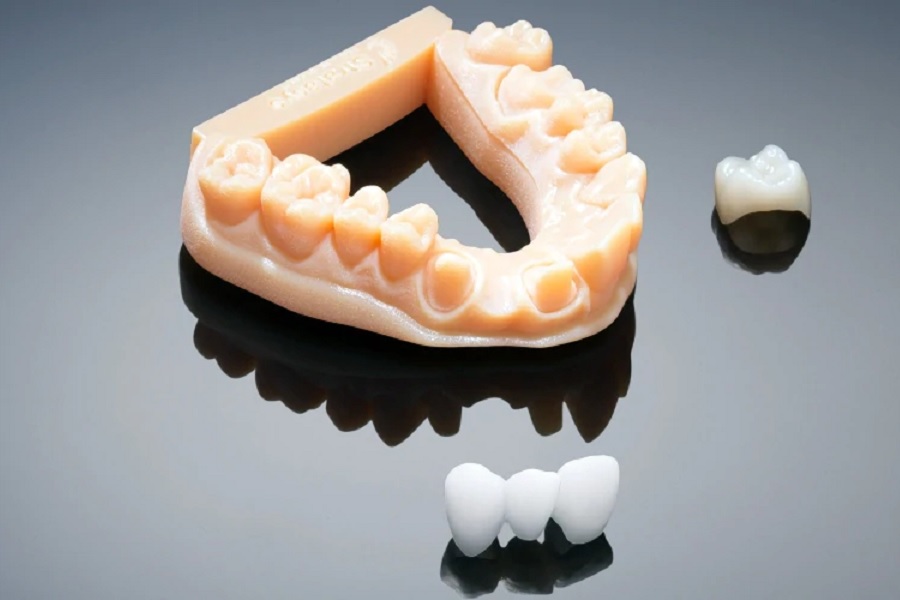

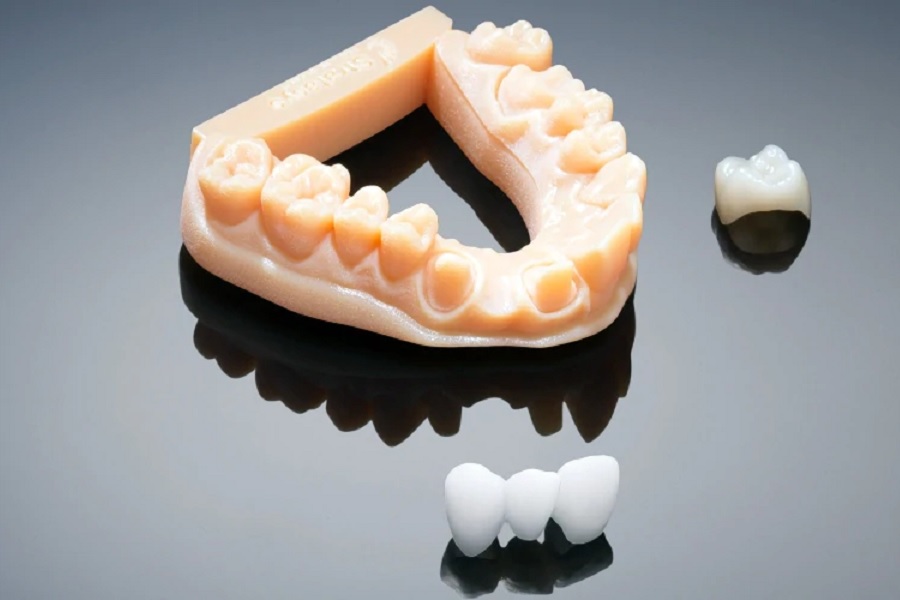

The advent of 3-D (3-Dimensional) printing technology in dentistry has given the practitioner access to options that were previously only available to dental labs. In the past ten years, 3D printing technology has become more affordable for clinicians, enabling them to provide patients with therapies that are more precise, economical, and quick. Working models, prosthodontic restorations, orthodontic devices, surgical guides for implant placement, and maxillofacial prostheses can all be produced using this innovative technique. In this article, we will review Dental 3D print methods in a specialized way.

What are the types of Dental 3D print methods?

The information gathered from cone beam computed tomography (CBCT) and intraoral optical scanner (IOS) pictures forms the basis of 3D printing technology. Afterward, this data is transformed into standard tessellation language (STL), which enables it to be imported into 3D modeling software and modified to satisfy the needs of the physicians for manufacture. Clinicians then modify the files and upload them to their preferred printer. Digital light processing (DLP), material jetting, and stereolithography (SLA) are the three most used 3D printing techniques in dentistry (MJ). On top of the printer’s build platform, these machines produce a product using additive manufacturing methods. the ability to create a variety of materials, including the metal, ceramic, and thermoplastic resin.

After production is finished, post-manufacturing activities are carried out to guarantee that the product is flawless and has been properly cured; the scope of these procedures depends on the material and printer type used. It should be noted that each printer type’s accuracy and precision heavily depend on the type of 3D printer utilized, the technology, the materials employed, the settings selected in the software, and the post-manufacturing refining process. The interconnection of all of these factors has a greater impact on overall quality than the variations in SLA, DLP, and MJ manufacturing processes. In the following, we will get to know the three technologies used in Dental 3D print methods.

SLA: One of the oldest Dental 3D print methods

SLA is one of the most popular and established Dental 3D print methods in dentistry. These printers overlay a liquid photopolymer resin that has been cured by an ultraviolet (UV) laser. While the laser polymerizes each layer of the resin it meets, liquid resin is kept in a vat. The build platform is lowered after the first resin layer has dried, and succeeding layers of resin are cured on top of one another. A UV oven or solvent bath must be used to harden the product once it has been refined of extra resin and support struts. The benefits of SLA printing are its rapid output, high resolution, the comparably inexpensive cost to other types of 3D printers, and capacity for complex design construction.

High-end SLA printers can create surgical guides, splints, occlusal guards, complete dentures, interim crowns, and orthodontic aligners. The most common 3D printer in the dental industry is an SLA printer since it can create a wide variety of products with incredibly exact outcomes.

DLP technology

DLP technology is similar to SLA printing techniques in that it uses the same curing, polymerization, and build-up processes, but uses a different light source—digital projectors—in its printers. This method is also one of the most popular Dental 3D print methods. When printing on a wide scale, digital projectors enable simultaneous complete polymerization of an entire material layer in the x-y axis, making this a far faster fabrication process. Resolution and surface detailing is sacrificed for speed in DLP large-scale printing operations, but these qualities are recovered when build volume is decreased.

Nonetheless, voxel lines are frequently produced on items by digital projector light sources. These lines result in tiny rectangular steps and have an impact on how curved edges are formed. To obtain clearly defined surface features, voxels must be refined through post-manufacturing alteration or fusing/detailing agents. Sandblasting is the primary method used for post-manufacturing alteration, while fusing/detailing agents are special liquids used to fuse/melt voxels together, both of which produce a more desirable surface quality.

Even with this shortcoming, small-scale DLP printing processes can achieve excellent feature resolution down to a few micrometers, making them perfect for goods that need great accuracy. Complete and partial dentures, thermoform models, surgical guides, single and multi-unit wax-ups, and DLP printers can all be printed with this accuracy. Costs are associated with this accuracy, volume, and speed; generally speaking, DLP printers are more expensive than their SLA equivalents.

material jetting (MJ): One of the most modern Dental 3D print methods

A new technique, material jetting (MJ), has gained popularity due to its higher production capabilities while SLA and DLP technologies have a firm grasp on the dental industry’s 3D printer market. MJ as one of the best Dental 3D print methods uses a similar approach to those of home ink printers. Using the printer’s nozzle, a light-sensitive polymer is blasted onto the build platform of the printer. Each layer is then individually cured by UV light. MJ printers can produce goods with the same level of accuracy as SLA and small-batch DLP printers without the need for post-manufacturing adjustments. These printers also have the ability to print a variety of materials inside the same print cycle, which is a special feature.

These materials are highly adaptable and particularly appealing for their potential use in esthetically complicated applications because of their variety in color, biomechanical characteristics, and textures. To produce crowns, multi-unit prostheses, implant models, surgical guides, detachable partial dentures, and different orthodontic appliances, MJ printing is therefore preferred. These printers are often huge in size and use unique material mixes. Which reduces their suitability for producing a wide variety of items and raises manufacturing costs. It is to be anticipated that as 3D printing and material jetting develop more materials will be made available to practitioners. Because this cause increasing the marketability of these processes for the dentistry industry.

The work of dentists has become easier with Dental 3D printing

3D printers have become a necessary and widely used tool in many industries. In recent years, Dental 3D print methods have also revolutionized the field of dentistry. Using these methods, dentists can produce all kinds of Implants, Aligners and Retainers, Crowns and Bridges, etc. with the highest precision and quality. Among other advantages of using dental 3D printers, we can mention cost reduction, increasing the speed of the treatment process, easy use for dentists, and the possibility of accessing new equipment and treatment methods.

Dental 3D print methods | Everything you need to know _______________________________________________________

Dental 3D print methods revolutionized dentistry

The advent of 3-D (3-Dimensional) printing technology in dentistry has given the practitioner access to options that were previously only available to dental labs. In the past ten years, 3D printing technology has become more affordable for clinicians, enabling them to provide patients with therapies that are more precise, economical, and quick. Working models, prosthodontic restorations, orthodontic devices, surgical guides for implant placement, and maxillofacial prostheses can all be produced using this innovative technique. In this article, we will review Dental 3D print methods in a specialized way.

What are the types of Dental 3D print methods?

The information gathered from cone beam computed tomography (CBCT) and intraoral optical scanner (IOS) pictures forms the basis of 3D printing technology. Afterward, this data is transformed into standard tessellation language (STL), which enables it to be imported into 3D modeling software and modified to satisfy the needs of the physicians for manufacture. Clinicians then modify the files and upload them to their preferred printer. Digital light processing (DLP), material jetting, and stereolithography (SLA) are the three most used 3D printing techniques in dentistry (MJ). On top of the printer’s build platform, these machines produce a product using additive manufacturing methods. the ability to create a variety of materials, including the metal, ceramic, and thermoplastic resin.

After production is finished, post-manufacturing activities are carried out to guarantee that the product is flawless and has been properly cured; the scope of these procedures depends on the material and printer type used. It should be noted that each printer type’s accuracy and precision heavily depend on the type of 3D printer utilized, the technology, the materials employed, the settings selected in the software, and the post-manufacturing refining process. The interconnection of all of these factors has a greater impact on overall quality than the variations in SLA, DLP, and MJ manufacturing processes. In the following, we will get to know the three technologies used in Dental 3D print methods.

SLA: One of the oldest Dental 3D print methods

SLA is one of the most popular and established Dental 3D print methods in dentistry. These printers overlay a liquid photopolymer resin that has been cured by an ultraviolet (UV) laser. While the laser polymerizes each layer of the resin it meets, liquid resin is kept in a vat. The build platform is lowered after the first resin layer has dried, and succeeding layers of resin are cured on top of one another. A UV oven or solvent bath must be used to harden the product once it has been refined of extra resin and support struts. The benefits of SLA printing are its rapid output, high resolution, the comparably inexpensive cost to other types of 3D printers, and capacity for complex design construction.

High-end SLA printers can create surgical guides, splints, occlusal guards, complete dentures, interim crowns, and orthodontic aligners. The most common 3D printer in the dental industry is an SLA printer since it can create a wide variety of products with incredibly exact outcomes.

DLP technology

DLP technology is similar to SLA printing techniques in that it uses the same curing, polymerization, and build-up processes, but uses a different light source—digital projectors—in its printers. This method is also one of the most popular Dental 3D print methods. When printing on a wide scale, digital projectors enable simultaneous complete polymerization of an entire material layer in the x-y axis, making this a far faster fabrication process. Resolution and surface detailing is sacrificed for speed in DLP large-scale printing operations, but these qualities are recovered when build volume is decreased.

Nonetheless, voxel lines are frequently produced on items by digital projector light sources. These lines result in tiny rectangular steps and have an impact on how curved edges are formed. To obtain clearly defined surface features, voxels must be refined through post-manufacturing alteration or fusing/detailing agents. Sandblasting is the primary method used for post-manufacturing alteration, while fusing/detailing agents are special liquids used to fuse/melt voxels together, both of which produce a more desirable surface quality.

Even with this shortcoming, small-scale DLP printing processes can achieve excellent feature resolution down to a few micrometers, making them perfect for goods that need great accuracy. Complete and partial dentures, thermoform models, surgical guides, single and multi-unit wax-ups, and DLP printers can all be printed with this accuracy. Costs are associated with this accuracy, volume, and speed; generally speaking, DLP printers are more expensive than their SLA equivalents.

material jetting (MJ): One of the most modern Dental 3D print methods

A new technique, material jetting (MJ), has gained popularity due to its higher production capabilities while SLA and DLP technologies have a firm grasp on the dental industry’s 3D printer market. MJ as one of the best Dental 3D print methods uses a similar approach to those of home ink printers. Using the printer’s nozzle, a light-sensitive polymer is blasted onto the build platform of the printer. Each layer is then individually cured by UV light. MJ printers can produce goods with the same level of accuracy as SLA and small-batch DLP printers without the need for post-manufacturing adjustments. These printers also have the ability to print a variety of materials inside the same print cycle, which is a special feature.

These materials are highly adaptable and particularly appealing for their potential use in esthetically complicated applications because of their variety in color, biomechanical characteristics, and textures. To produce crowns, multi-unit prostheses, implant models, surgical guides, detachable partial dentures, and different orthodontic appliances, MJ printing is therefore preferred. These printers are often huge in size and use unique material mixes. Which reduces their suitability for producing a wide variety of items and raises manufacturing costs. It is to be anticipated that as 3D printing and material jetting develop more materials will be made available to practitioners. Because this cause increasing the marketability of these processes for the dentistry industry.

The work of dentists has become easier with Dental 3D printing

3D printers have become a necessary and widely used tool in many industries. In recent years, Dental 3D print methods have also revolutionized the field of dentistry. Using these methods, dentists can produce all kinds of Implants, Aligners and Retainers, Crowns and Bridges, etc. with the highest precision and quality. Among other advantages of using dental 3D printers, we can mention cost reduction, increasing the speed of the treatment process, easy use for dentists, and the possibility of accessing new equipment and treatment methods.